Hardwire MIG welding is one of the most versatile welding processes. Also grind a minor groove that will help you in vertical up welding.

Mig Welding Basics Part 6 Vertical Uphill Tee Joint Drill

When Vertical MIG Welding Goes Wrong.

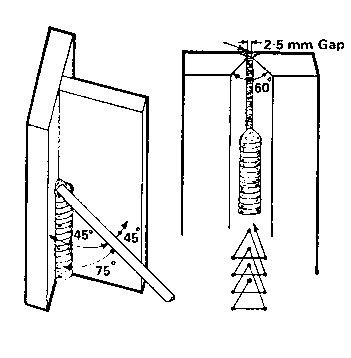

. This pattern greats a flat stack of dimes. Hold the MIG gun between an angle of 35 to 45 degrees. Metal inert gas uses an electric arc with filler wire.

Use the right wire. When it comes to vertical welding doing both up and downward will be hard. Because vertical down welding helps avoid excessive melt-through welders sometimes place very thin materials in the vertical position even if they can weld them in the flat position.

Whipping is distinctly different from weaving and the circle pattern technique is a combination of the two. When you have a fillet weld in a tee or lap joint we also call it a 3F position. Ad Get the top brands you need at the prices you want.

Vertical Up Position. It scatters the filler metal out more resulting in a fine bead. When you choose to MIG weld something there are several different techniques you can use to lay a quality weld.

Ad Search our 4000 products with the insights on how to do the job right. Like weaving there is a separate forehand and backhand method for each pattern. When you should not weave for MIG welding you have three other options.

The vertical up MIG welding portion technique is one of the most challenging positions. If its a butt joint with a groove weld its a 3G position. Flat welds horizontal welds vertical down vertical up and overhead welding.

You need to be able to control your travel speed so that you can pump enough metal into the joint. Flat and horizontal welds are fairly easy but vertical uphill welds contend. Your settings should be hot enough to penetrate without sending the filler running down the joint.

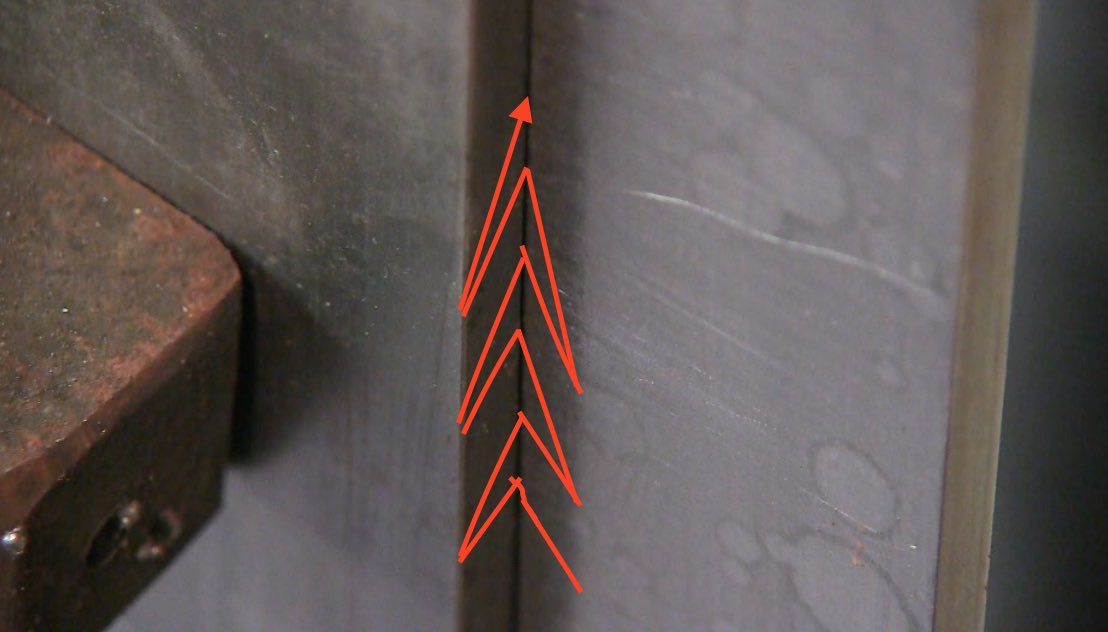

To perform vertical up welds you will first need to open the front or side lid depending on the. The upside down v is one of the most effective techniques for vertical mig welding of lap and. If your having to weld vertical up with mig and your welding anything thicker then 14 material run a dual shield wire e71t and not only will the weld appearance be much bettar but you can easily weld vertical up and not have the puddle fall out.

They will completely create an upright bead with the aid of a stinger. 7 rows With a MIG welder you can weld in the vertical position if you use the common short-circuit. When welding vertical down begin at the top of a joint and weld down.

A vertical weld can be performed in. This pattern makes a nice contour to the weld with the end result looking like butterfly wings. No molten is produced thereby making the process clean and comfortable.

For thin metal where burn-through is a concern direct the wire away from the weld puddle. If you have to chase your weld downhill youre not getting the right penetration you need for your weld. You might need a pre-weld setup ready to make sure your vertical welding can be done efficiently and with ease.

If you insist on running hard wire on vertical up then. While welding most people use the vertical down process as gravity supports the process. Ad Shop over 70000 Products 1500 Of The Best Brands.

While MIG welding is one of the easiest welding techniques in use it requires a specific skill set that welders will need to learn to produce high quality MIG welds. If I have an L shaped area to weld with one of the two sides being vertical I will run a J type pattern ware I creat a ramp with each stroke to run up and hold it aginst the vertical piece. Although this can produce a sound weld using a weave as a welding beads pattern can benefit wider joints and straight welds.

We care about your DIY automotive projects and want you to be 100 satisfied. Get Vertical Mig Welding Pattern Background. Welding vertical MIG requires not just skills but plenty of it.

Thus you will need to take certain considerations such as a reduction in amperage of your machine at first because the hotter the puddle the more easily it will drop to the ground. Most of the MIG welders dont like to weave or use any welding beads pattern. Again as we go against gravity it is better to reduce the voltage and amperage to about 10-15 of its initial values.

To work on a vertical up position you need to create a shelf to work on an upright position. From novice to professional welders rest assured that if you want it we have it. The vertical position is one of the four basic welding positions in which the joints axis is vertical to the ground at an angle ranging from 45 to 90.

Those options are comprised of the circle holding still and whipping. 05-02-2012 0458 PM. Vertical MIG welding is one of the most difficult and tiring welding position to master.

Vertical welding position requires you to work against the force of gravity. If youre stick welding something with a vertical joint the filler rod can easily lay a weave pattern bead using the right-hand technique. One of these specific welding techniques is welding vertical up which is one of the most difficult types of MIG welds.

The constantly fed wire functions to melt and fill the gap.

Vertical Up Settings Help Mig Welding Forum

This Vertical Mig Welding Technique Will Penetrate

Vertical Uphill Welding Technique

Smaw Weave Patterns Google Zoeken Soldadura Mig Proceso De Soldadura Proyectos De Soldadura

Solid Wire Vertical Up Miller Welding Discussion Forums

0 comments

Post a Comment