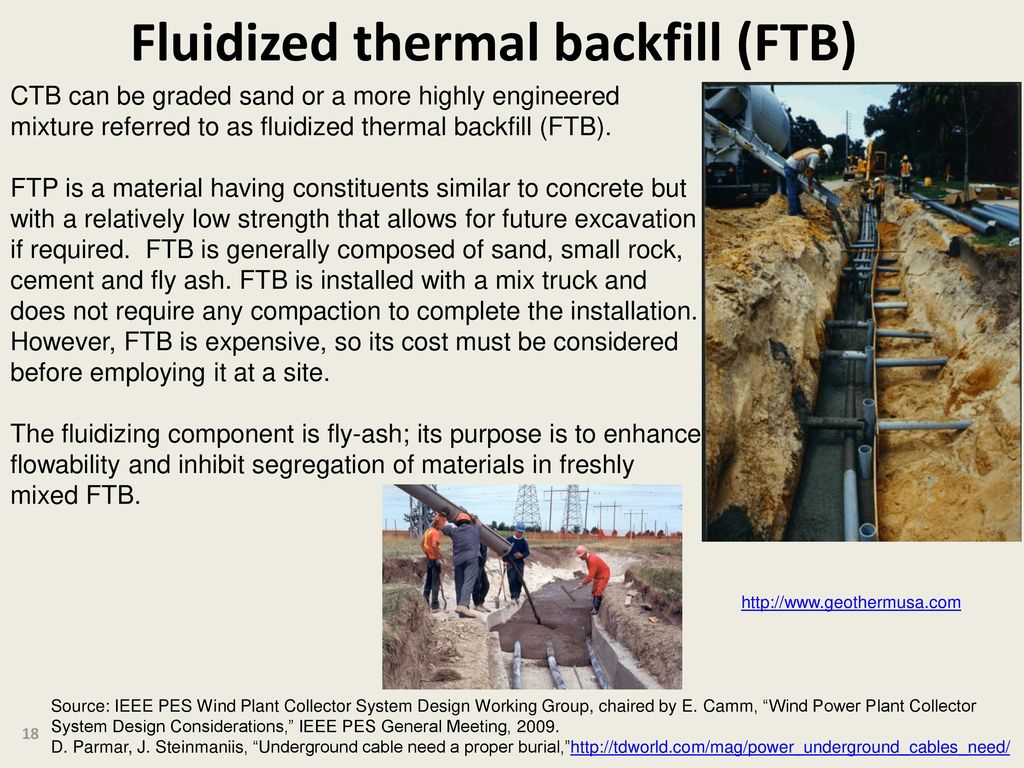

One of the best performing backfills was a Fluidized Thermal Backfill FTB containing sand aggregate cement and fly ash. You know we have found that in most cases realistic dry soil is in the 200 maybe as high as 500 row range.

Collection Circuits J Mc Calley Highlevel Design Steps

I am always reluctant to believe.

. Fluidized Thermal Backfill a trademark of Geotherm Inc is a form of controlled low-strength material composed of certain types of stone sand fluidizing agents and cement specifically designed to dissipate the heat generated by underground electric transmission cables within city streets or on rural wind farms. A weil formulated Fluidized Thermal Backfill FTB is a cast effective means 01 providing the optimum thermal resistivity and thermal stability characteristics. 18 Aug 03 0956.

Up to 10 cash back If needed these can be designed as Fluidized Thermal Backfills FTBs which are self-levelling and self-compacting flowable mixes constituted by a proper combination of hydraulic binder aggregates fly ash and water 5 6 7. MIX DESIGN The task of developing a fluidized thermal backfill proceeded from a clear under standing of the thermal behaviour of a three phase material such as soil. 71 Type 1 Granular Backfill and Type 2 Culvert Gravel Supplying and placing of granular backfill and culvert gravel will be measured on a mass basis of hauled material.

Recordation to the theoretical mix design submitted and approved by the engineer. The method includes process steps of blending ingredients of stone sand and fly ash making a flowable thermal fill by mixing the blended stone sand and. The best backfill available in Brazil today is composed of materials from volcanic rocks that provide thermal resistivity of 1 Km W for driedmaterial.

Concrete used for conduit encasement shall meet the requirements of Mix Design 330-C-1700 as defined in SSPWC Section 201 See Appendix II TABLE 1. A typical mix design consists of 15 parts sand to 1 part cement mixed with about 10 parts water. Quantities of batched component materials shall match those specified in the FTB mix design within the tolerances specified in Section 6-0235C Conformance To Mix.

This also will include a thermal dryout curve. Afterwards concretes with extremely high thermal conductivities were developed 2. I am familiar with the concept but I need to find more detailed information such as performance data pricing installation requirements etc.

The FTB is an engineered material that has very low thermal resistivity even when totally dry and has very long thermal dryout times thermally very stable. However this backfill is quite strong and thus would be difficult to excavate. FTB Fluidized Thermal Backfill So there are just some fundamental principles and these are things electrical engineers work with Im not sure thermal people.

Choose the design thermal rho values for the native soil and thermal backfill. Mix Design for a Low Strength Fluidized Thermal Backfill FTB and testing and approval of three local suppliers that are within 50 miles of Los Angeles City Hall. Structures shall conform to the Department mix design Number DWP 3000-10 as defined in Departments Standard Drawing C702-50 See Appendix II TABLE 1.

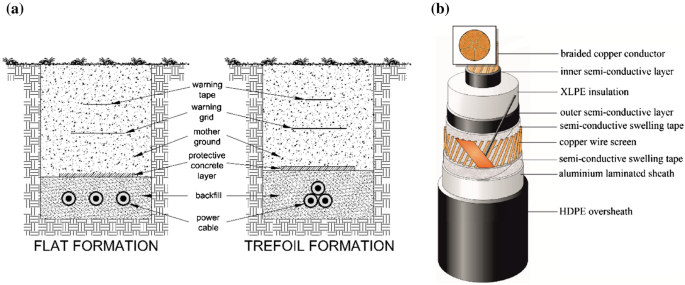

Flowable fill is an engineered backfill consisting of natural aggregates a fluidizing agent cementitious material and water that flows easily into the trench instead of attempting to compact. Engineered backfill materials CBS Cement Blended Sand FTB Fluidized Thermal Backfill which provides low thermal resistivity and enhance the performance of the cables. The mix design shall conform to SCL 715000 Fluidized Thermal Backfill 42 Conformance to Mix Design.

Choose the design thermal rho values for the native soil and thermal backfill based on. Backfill o SVP Public Works Contract 2114B Project Specifications 2012 Section 3310 Fluidized Thermal Backfill o Transmission Distribution World April 1 2003 Underground Cables Need a Proper Burial Deepak Parmar and Jan Steinmanis Rescissions. 20 APPLICABLE DOCUMENTS R20 APPLICABLE DOCUMENTS 21 ASTM Standards C 403 The intent of the guide is to use the most current Time of Setting of Concrete.

FTB transfers heat away from power cables allowing them. Flowable fill is commonly referred to as controlled low strength material CLSM controlled density fill CDF and slurry. Unit weight of unhardened CLSM is not needed for verification of non air - entrained C LSM mixtures.

Source and design the fluidized thermal backfill or compacted granular backfill based on locally available materials. InTerras Thermal Product Lines of Fluidized Thermal Backfill FTB Thermal Concrete and Thermal Grout are the solution to your heat transfer requirements. Our products will create a stable thermal environment for the expensive high voltage cables assisting them to operate efficiently at safe temperatures and for the life expectancy anticipated.

Thermal Backfill for Underground Power Cable Installations August 11 2014 C-UG-2050 Transmission Distribution Standards Page 1 of 4 Application Flowable Thermal Backfill FTB is placed around power cable conduit runs to more effectively dissipate heat generated by the cables into the surrounding environment. Fluidized Thermal Backfill FTB is used to encase and cover underground power conduits that will contain transmission or distribution cables which may operate at or above normal ampere capacity ampacity. Does anybody know where I can get some hard data on fluidized thermal concrete aka Fluidized Thermal Backfill -FTB for installation of underground power cable.

Prior to placement the contractor shall submit to SCL the proposed FTB mix design for approval. Achieving soil density is needed in the restricted trench areas near cables or around cable pipe groups where proper compaction is difficult. Weigh scale tickets for each truck shall be provided to the Engineer or his representative for verification and approval prior to unloading of backfill material.

This also will include a thermal dryout curve. FTB can be madetromlocally available aggregates and is installed as a con trolled density. Source and design the fluidized thermal backfill or compacted granular backfill based on locally available materials.

The thermal conductivity of the composite media depends on the thermal conductivity of the individual components their proportion and nature of dispersion. Thermally stable fluidized backfill began in the eighties 1.

Cable Backfill Geotherm Australasia

Analysis Of An Application Possibility Of Geopolymer Materials As Thermal Backfill For Underground Power Cable System Springerlink

Local Issues 1 Collection Circuits J Mccalley Ppt Download

Fluidized Thermal Backfill Geotherm Usa

Underground Power Cables Geotherm Usa

Typical Mix Proportions Of A Clsm Mixture For Trench Backfilling Data Download Scientific Diagram

0 comments

Post a Comment